China gearbox speed reducer manufacturer

Electric motor gearbox supplier, industrial motor reducer manufacturer

China gearbox speed reducer manufacturer

Electric motor gearbox supplier, industrial motor reducer manufacturer

R177 helical coaxial gear motor

Description

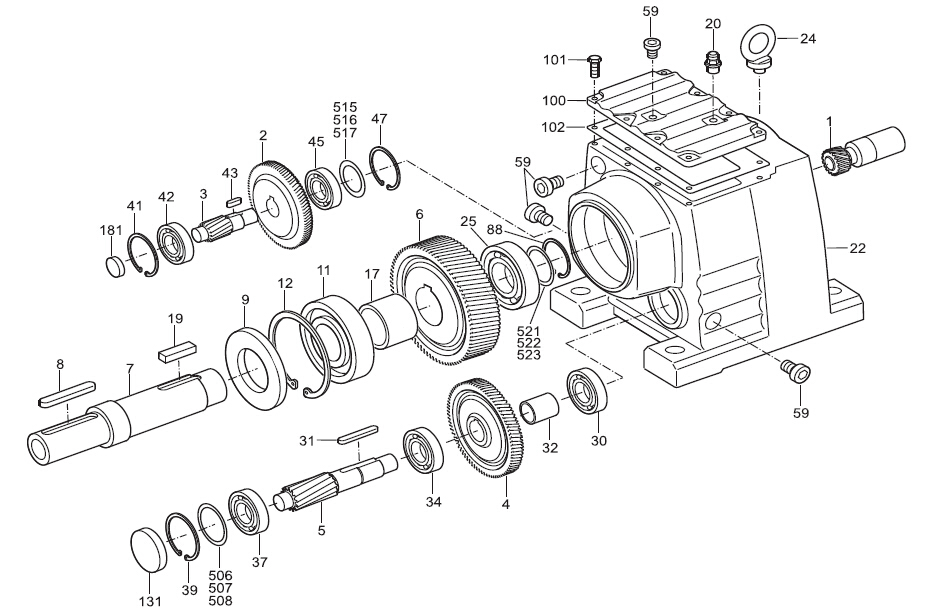

For R coaxial gear reducers, the boxes are cast precisely by high material And processed at processing center; The gears are made of high-quality alloy steel, are treated with surface hardening and toothed; And the key parts are imported.

coaxial gear reducer Characteristic:

1. Good available capability & reliability

2. Good temperature exchange capability & high strengthens

3. Carburized and grinded teeth

4. Good fabricate capability, can be fabricated with other reducer to realize low-speed transmission

R series helical coaxial gear reducer hardened precision machined to ensure parallel shaft and locating bearing requirements, forming helical coaxial gear reducer assembly configured for various types of motor , a combination of mechanical and electrical integration , fully guaranteed deceleration motor product quality attributes.

Helical inline DC Gear motors Data

Manufacturing precision :4- 5

Output speed :0.05 -809

Output Torque : Up to 15,000

Power :0.12-160KW

Helical inline DC Gear motors Applications

1. Conveyor machinery

2. Craning

3. Bagger

4. Enginery for foot industry

5. Washer

6. working machine

7. Cropping & shearing machine

8. woodworking machine

9. Machines for plastic industry

Helical inline DC Gear motors Feature:

(1) The building block design.

(2) Housing is unitary, structure rigidity is good.

(3) Fit all types of motors.

(4) For different type machines.

(5) Ratio: 2-stage is 5~24.8, 3-stage is 27.2~264, ratio of combination is up to 18125.

(6) Solid shaft output, 2-stage efficiency 96%, 3-stage efficiency 94%, DR/DR efficiency 85%.

(7) Permit the positive opposite side revolve.