- Brief Introduction

VF worm gear reduction motor is designed with the most advanced materials and manufacturing technology. It has the characteristics of compact structure, reliable quality, various installation positions and torque limiter, etc., helical gear - worm gear and double worm gear deceleration can provide more driving system.

- Product Features

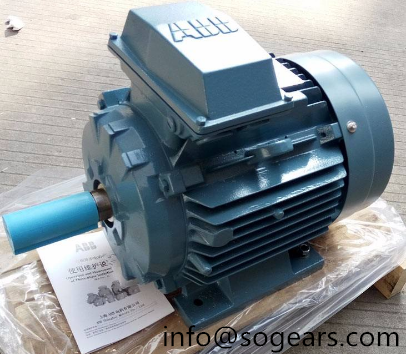

VF worm gear reduction motor adopts single-stage worm and worm gear transmission, compact structure, high quality aluminum alloy die-casting box and light weight. Good heat exchange performance, fast heat dissipation, easy installation, flexibility and lightness. Low noise and durability.

- Scope of using

VF worm gear reduction motor is uitable for food, cooking machinery, printing machinery, woodworking machinery, small textile machinery, rubber machinery, small chemical machinery, plastic machinery.

- Product Specifications

VF worm gear reduction motor basic structure is mainly composed of transmission parts worm gear, worm shaft, bearing, box and accessories. Can be divided into three basic structure parts: box, worm gear, worm, bearing and shaft combination. The box body is the base of all accessories in the worm gear reducer. It is an important part to support the fixed shafting parts, ensure the correct relative position of the transmission parts and support the load on the reducer.

VF worm gear reduction motor mainly function to transfer the movement and power between the two staggered shaft, bearing and shaft is the main role of power transfer, operation and improve efficiency.

- Direction for Using

VF worm gear reduction motor in line with the national standard gb10085-88 cylindrical worm gear parameters on the basis of the absorption of advanced technology at home and abroad, unique and novel "square box" shape structure, box shape is beautiful, die-cast from high-quality aluminum alloy.

VF worm gear reduction motor has been widely used in various industrial production process equipment of mechanical reducer, is the modern industrial equipment to achieve large torque, large speed ratio, low noise, high stability of mechanical reducer transmission control device of the best choice.

- Usage Support

Please do not put pressure on the output parts of the reducer and the box when installing. Please meet the corresponding requirements of coaxiality and perpendicularity between the machine and the reducer when connecting. The VF worm gear reduction motor should be replaced with lubricating oil after the initial operation of 400 hours, and the subsequent oil change cycle is about 4000 hours. Pay attention to keep the appearance of reducer clean, timely remove dust, dirt to facilitate heat dissipation

Christine Zhu ( Sales Department; Miss. )

NER GROUP CO.,LIMITED

Tel:+86-535-6330966

Mobile:+86-13688909643

http://www.bonwaygroup.com/

https://twitter.com/gearboxmotor

https://www.facebook.com/sogears1993

Viber/Line/Whatsapp/Wechat: 008613688909643

Email:

Skype ID:

Factory Add: No.5 Wanshoushan Road, Yantai, Shandong Province, China (264006)