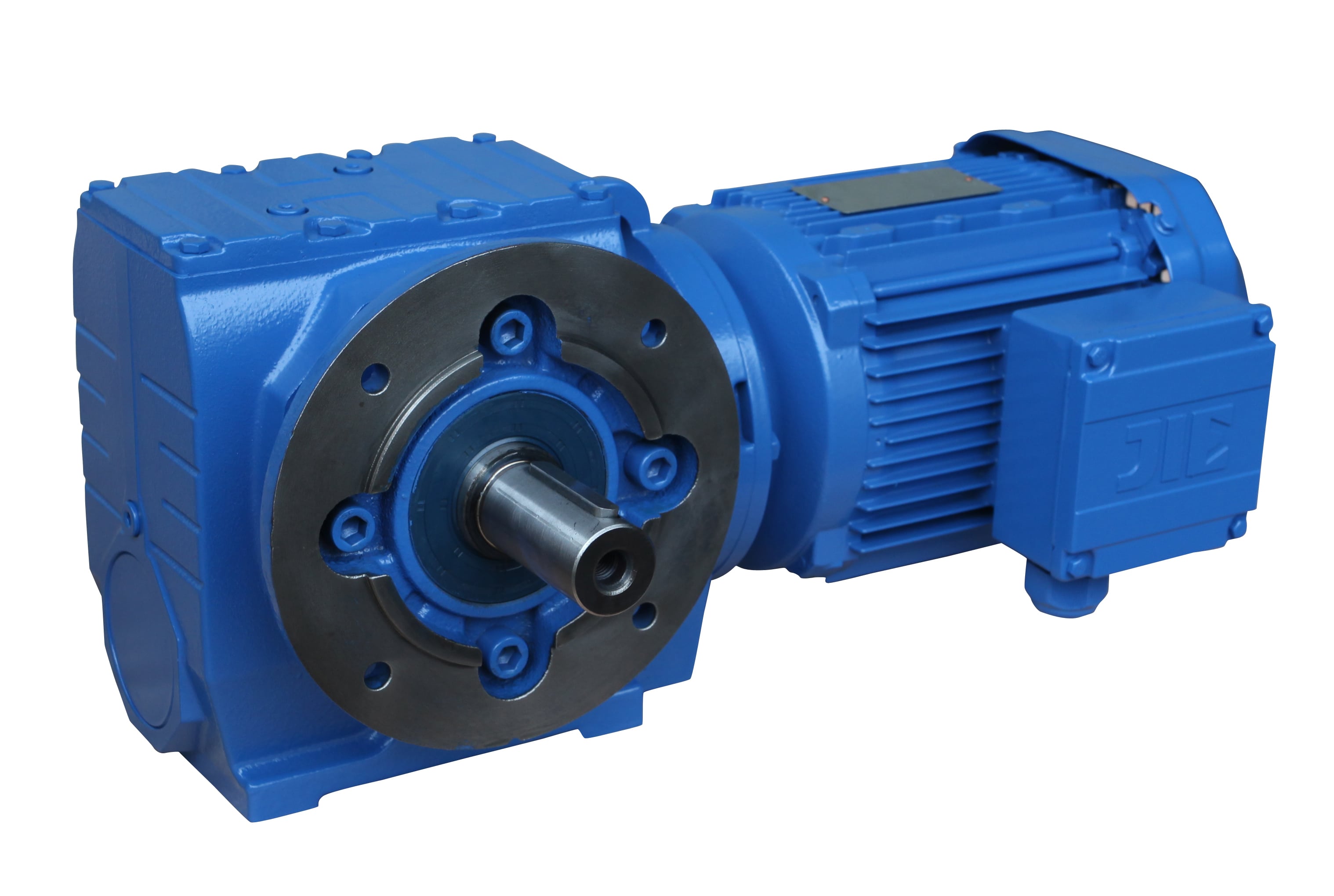

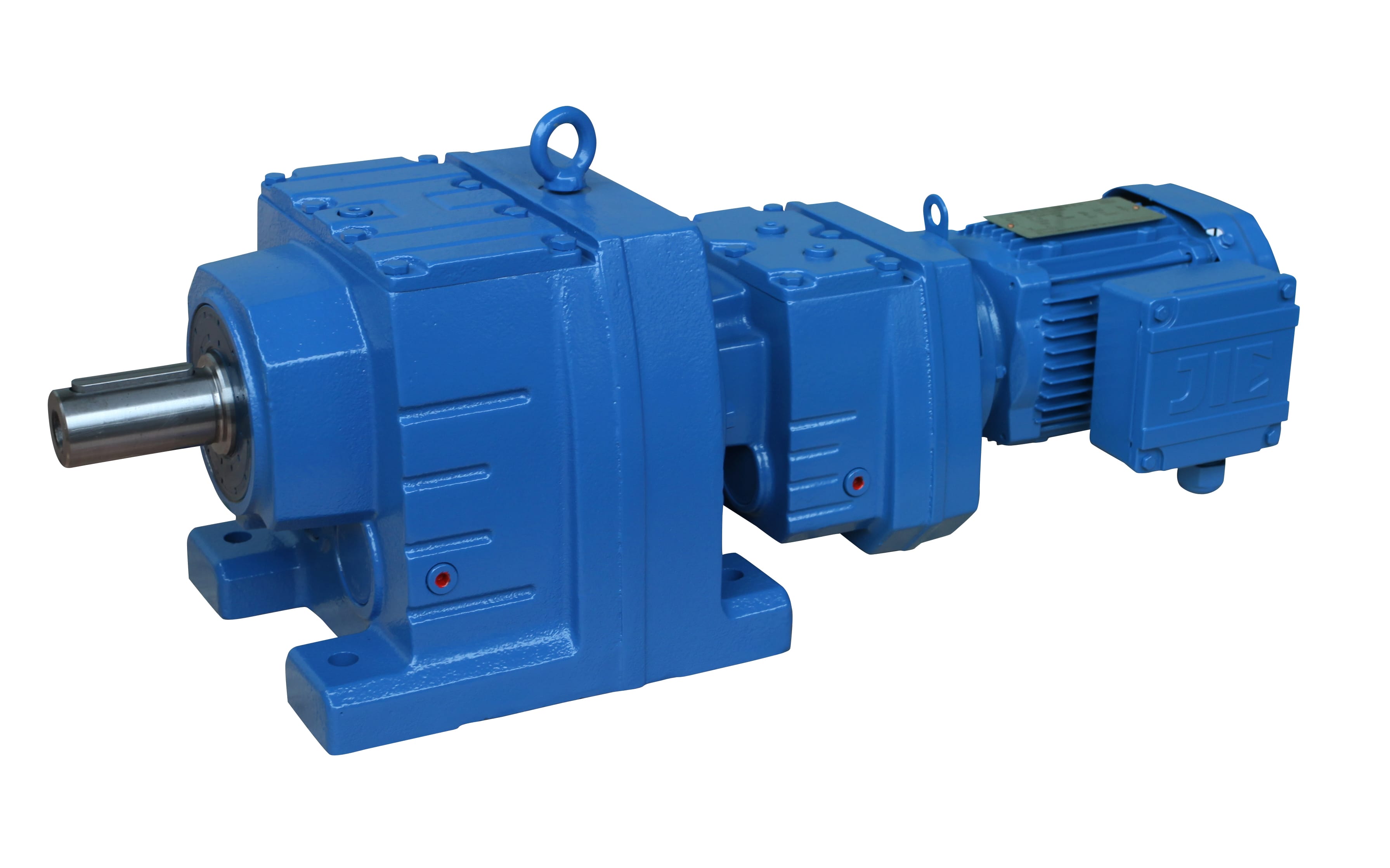

The worm geared motors is a transmission drive with compact structure, large transmission ratio and self-locking function under certain conditions. It is widely used in a large number of industries and mechanical products. The wide range of applications is prone to various problems. NER GROUP analyzes some common causes of problems and points out some common treatment methods for geared motors:

The worm geared motors is a transmission drive with compact structure, large transmission ratio and self-locking function under certain conditions. It is widely used in a large number of industries and mechanical products. The wide range of applications is prone to various problems. NER GROUP analyzes some common causes of problems and points out some common treatment methods for geared motors:

Worm and worm geared motors common problems and solutions common problems and causes:

1. The geared motors are with heat and oil leakage, in order to improve efficiency, turbine geared motors generally use non-ferrous metals for turbines, and worms use harder steel. Due to the sliding friction transmission, more heat is generated during operation, which causes a difference in thermal expansion between the parts of the reducer and the bees, thereby forming a gap in a mating surface, and the lubricating oil is thinned due to an increase in temperature, which is liable to cause leakage, resulting in leakage. There are four main reasons for this situation. One is that the material is not properly matched; the quality of the meshing friction surface is poor; the third is that the amount of lubricant added is not correct; the fourth is the poor assembly quality and environment.

2. Turbine wear. The turbine is generally made of tin bronze, and the paired worm material is hardened to 45°C to HRC4555 or 40Cr hardened to HRC5055 and then ground to a roughness of Ra0.8μm by a worm grinder. The reducer wears very slowly during normal operation, and some geared motors can be used for more than 10 years. If the wear speed is faster, it is necessary to consider whether the selection is correct, whether it is overloaded, and the material, assembly quality or use environment of the worm geared motors.

3. Drive small helical geared motors. It usually occurs on a vertical mounted geared motors, mainly related to the amount of lubricant added and the type of oil. When the vertical installation is installed, it is easy to cause insufficient lubricant. When the geared motors stops running, the transmission gear between the motor and the gear is lost, and the geared motors are not protected by the lubrication. In the geared motors, the gears are mechanically worn or even damaged due to the lack of effective lubrication.

3. Drive small helical geared motors. It usually occurs on a vertical mounted geared motors, mainly related to the amount of lubricant added and the type of oil. When the vertical installation is installed, it is easy to cause insufficient lubricant. When the geared motors stops running, the transmission gear between the motor and the gear is lost, and the geared motors are not protected by the lubrication. In the geared motors, the gears are mechanically worn or even damaged due to the lack of effective lubrication.

4. The worm bearing is damaged. When a fault occurs, the gearbox is sealed well in time, and it is often found that the gear oil in the geared motors is emulsified, and the bearing is rusted, corroded, and damaged. This is because the condensed water produced by the gear oil temperature rises and cools after mixing for a period of time. Of course, it is also closely related to bearing quality and assembly process.

NER GROUP LIMITED is a professional manufacturer for manufacturing geared motors for several years from China.

We believe that we can cooperate with you on this business and please contact us if you are interested.

You are welcomed to visit our catalogue website for more information:

www.sogears.com

Mobile:+86-18563806647

www.guomaodrive.com

https://twitter.com/gearboxmotor

Viber/Line/Whatsapp/Wechat: 008618563806647

E-mail:

No.5 Wanshoushan Road, Yantai, Shandong,China