China gearbox speed reducer manufacturer

Electric motor gearbox supplier, industrial motor reducer manufacturer

China gearbox speed reducer manufacturer

Electric motor gearbox supplier, industrial motor reducer manufacturer

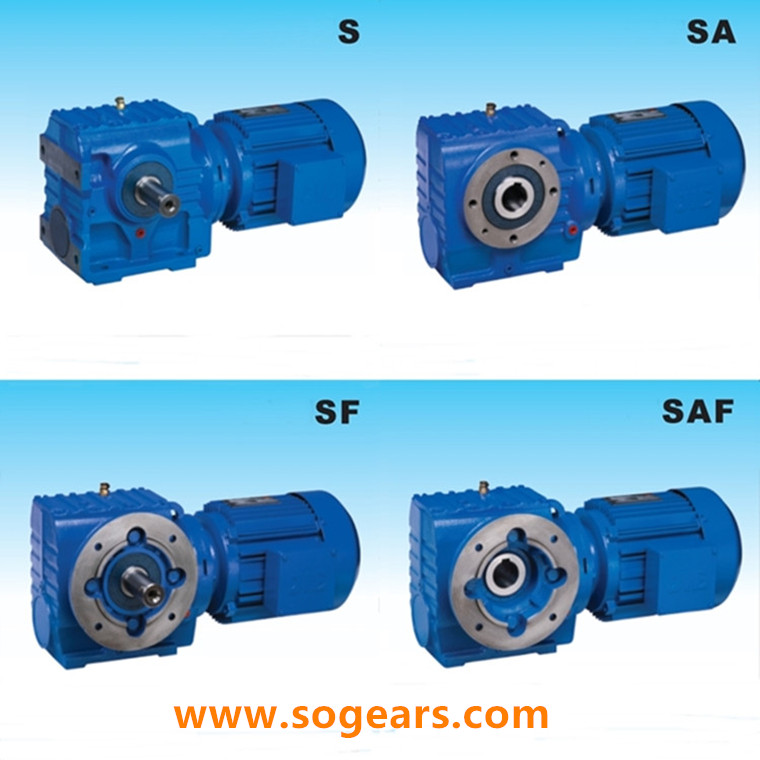

S100 helical worm gear motors

Description

worm helical gearmotors Description

series helical-worm gear reductor is different from ordinary ones for their reasonable structure,input using a pair of helical gear for deceleration to lower the rotary speed of worm,less heat, as well as ease of gaining larger gear ratio.Combined with AR and MB series,they can meet customers'different requirements.

worm helical gearmotors Material:

Housing: HT250 cast iron

Gear: 20CrMnTi H, high grade allo with carburization, surface hardness: 58-62HRC, center hardness: 33-48HRC, bronze alloy and spun casting in worm wheel

Grinding precision grade: ISO1328-1: 1995 class 5-6, surfaceness: 0.8, carburization depth: 0.6-1.5mm

Bearing: 42CrMo

helical worm gear speed reducers Site conditions

The helical worm gear speed reducers are suitable for the operation sites in the ambient temperatures from -10 degree to 40 degree and altitudes up to 1000m above the sea lever. They can be used both for clockwise running and anti clock wise running. There is no limitation to the specific application field. While applied in other aggressive operating atmosphere or environment conditions, please contact our technology department.

Based on modular combined system, SGR design and develop all kind series gearbox included helical worm gear speed reducers, which is the most common and advanced transmission device nowadays among international power transmission industry, with our strict quality criteria and quality control, we try our best to provide geared motor for conveyor belt with moderate price & high quality, replace oversea product in the field of Transmission Part.

Our Company

(1)Best quality,competitive price

(2)New design,favorable adaptability

(3)Delivery on time

(4)30 years in making gear box

(5)Safe,reliable,economical and durable

(6)Stable transmission,quiet operation

(7)High heat-radiating efficiency,high carrying ability

(8)Certificate of quality:ISO9001