China gearbox speed reducer manufacturer

Electric motor gearbox supplier, industrial motor reducer manufacturer

China gearbox speed reducer manufacturer

Electric motor gearbox supplier, industrial motor reducer manufacturer

S37 helical worm gear motors

Description

helical worm gear motors Characteristics

S37 series helical worm gear motors adopts the helical worm gears to make its structure more reasonable. S series not only has higher transmission efficiency and loading capability than those single-stage worm wheel transmission, but also smaller volume and appearance. Moreover, S series Helical Worm Gear Drives has higher transmission ratio, and can be combined with various gearboxes and speed variator to meet the different requirements.

S series Helical Worm Gear Drives has more sizes with a reduced variety of parts Increased power capacity, lower noise and higher efficiency by grinding and modifying gear The all-in-one box provides higher rigidity and higher vibration resistance. More ratios satisfy the need of accurate output speed. Helical Worm Gear Drives can be supplied for either horizontal or vertical installation in any angles.

Helical Worm Gear Drives Specifications

1, Large ratio

2, Great load-carrying capacity

3, Steady running

4, Low noise

5, High efficiency

6, Competitive price

7, Good quality

8, Good technology support

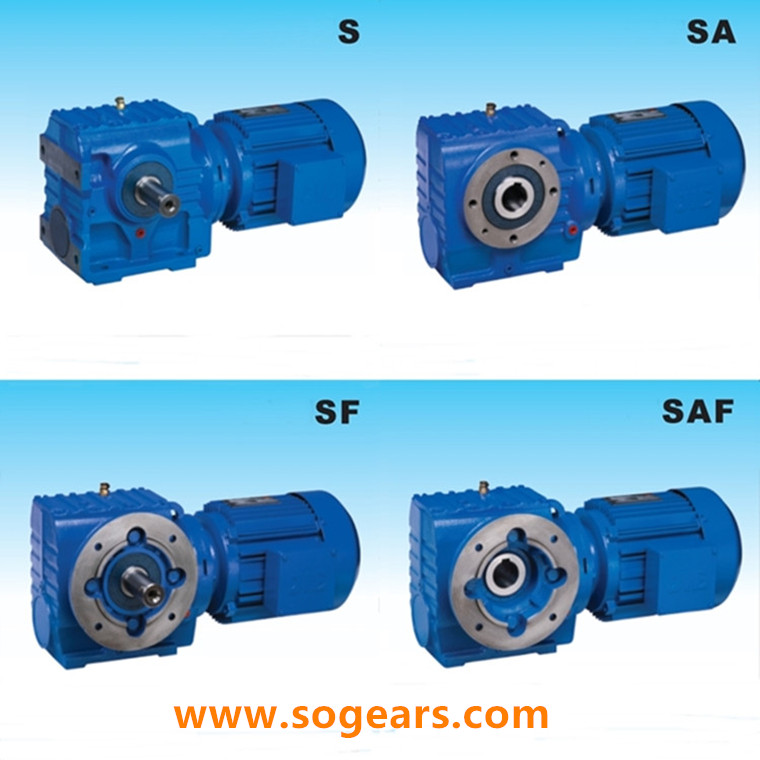

9, Mounting type: Foot mounted, flange mounted, torque armed mounted

10, Widely used in metallurgy, mining, steel, weighing, transportation, petrochemical, chemical, construction, textile, pharmaceutical, food, transportation, environmental protection, light industry, plastic, paper, parallel parking, lifting, Bridges, shipbuilding and other heavy industry department the mechanical transmission fields.coal equipment,ferrous metallurgy,mining machinery, paper machinery, rubber and plastics, petrochemical, lifting transportation, drink beer, food packaging, pharmacy and leather, textile dyeing and printing, environmental protection equipment, light industry machinery etc.

1.Specification: WS37~WS97, seven type totally.

2.Input Power: 0.12~22KW (Four-stage motor)

3.Output Torque: 10~4900N•m

4.Transmission ratio: 6.8~11267

5.Various ways of installation: foot mounting, input flange of B5. The foot amounting reducer has two machine-processed foot mounting surfaces.

| Housing (mono-block) | HT250 (cast iron) |

| Gear Pair | 20CrMnTi |

| Input/Output shaft material | 40CrMo Alloy steel |

| Motor shaft | 40Cr |

| Housing Hardness | HBS90-240 |

| Finish | Caburizing & Quenching |

| Design | Modularly designed , easy for exchangement with SEW product |

| Lubrication | VG220 |

| Model(7) | S37\S47\S57\S67\S77\S87\S97 |

| Ratio | 6.8-288 |

| Input Power | 0.12-22kW |

| Output Torque | 11-4530N.m |

| Output Speed | 4.86-206 RPM |

| Gear Accuracy | 6 to 4 Grade |

| Gear Surface hardness | HRC58°-62° |

| Input/Output shaft hardness | HRC25°-30° |

| Noise(Max) | 60-68dB |

| Tem.rise(Max) | 40°C |

| Tem.rise(Oil Max) | 50°C |

| Vibration | ≤20um |

| Backlash | ≤20Arcmin |

| Effeciency | Single stage 98%, Double-stage:96%, Three-stage:94% |

| Mounting Position | Foot / Flange Mounting |

| Motor | IP55 |

| Certification |

CE, ISO |