China gearbox speed reducer manufacturer

Electric motor gearbox supplier, industrial motor reducer manufacturer

China gearbox speed reducer manufacturer

Electric motor gearbox supplier, industrial motor reducer manufacturer

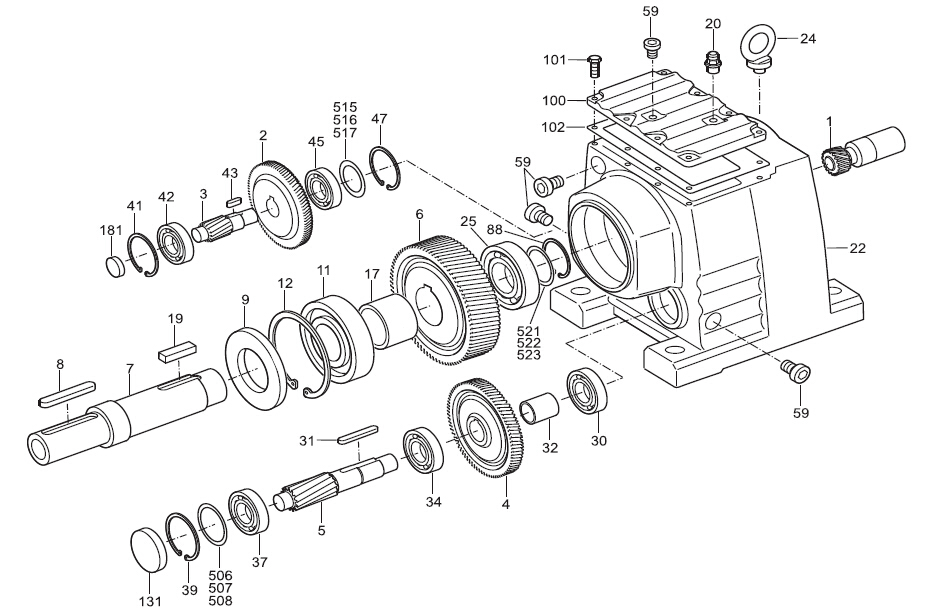

R177 inline helical gearbox

Description

helical-inline gearbox offer unsurpassed advantages in terms of weight, efficiency and interchangeability. The helical-inline gearbox are loaded with long life features industrial equipment users have come to expect. we offers a modular construction, which allows for the in-field addition of a specific base or flange needed to make a bolt-in replacement for dozens of popular reducer brands.

Helical Gear Motor Reductor Output Configuration

Foot and Flange mount

Metric or Inch series Solid Output shaft

Helical Gear Motor Reductor Input Configurations

IEC and NEMA motor Adaptors

Metric or Inch series Solid Output shaft

Helical Gear Motor Reductor Applicable AC motors

Integral motors and Brake motors - M series

IEC-normalized Motors and Brake motors - BN series

Single and Dual Speed Motors

helical-inline gearbox Main Brake Features

DC and AC supply

Faster Brake Engage/Disengage through Electronically

Controlled AC/DC Rectifier type SB, NBR, SBR (options)

helical-inline gearbox Main Motor Options

Thermistors and Thermostats sensor

Separate Supply Forced Ventilation

Line Driver and Push-Pull Incremental Encoder

helical-inline gearbox Features

Single-piece aluminum alloy housing vacuum impregnated with Resinol RT (MILSTD 276) for protection and sealing.

Factory-filled with premium Mobil Glygoyle 460 polyalkalene glycol lubricant.

Premium Viton® seal provide extra protection against entry of contaminants or loss of lubrication. Tandem seals available on input and output.

Oversized ball bearings on both input and output shafts.

Bearing spans optimized to allow for maximum overhung load capacity, enhanced durability and reliability—while minimizing shaft deflection.

All gearing is hardened and ground (AGMA Class 10 or better), for enhanced efficiency and noise reduction. Double reduction units are 96 – 97% efficient.

Removable inspection cover allows periodic inspection of gearing during routine maintenance.

Robust output shaft of high strength steel alloy for superior torque and overhung load capacities.

Permanently marked nameplate with output torque, ratio and maximum input horsepower.

Wide selection of accessory bases and flanges.

Mounting dimensions are interchangeable with many popular Helical Gear Motor Reductor.

Integral mounting bases and output flanges designed to interchange integral output flange also available to allow interchange with many industry standard sizes.

Available pre-assembled with LEESON or Lincoln Motors for the perfect Helical Gear Motor Reductor package.