China gearbox speed reducer manufacturer

Electric motor gearbox supplier, industrial motor reducer manufacturer

China gearbox speed reducer manufacturer

Electric motor gearbox supplier, industrial motor reducer manufacturer

Types of ZLYJ560 gearboxes

Description

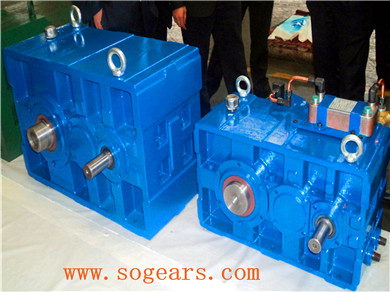

Extruder gearbox Product Description :

ZLYJ series plastic extruding gear reducer are high precision hardening tooth flank transmission part with thrust bearing housing. They are designed for plastic screw-rod extruder according to ZBJ19009-88. The gears and axes are made of high strength alloy steel. The gears are manufactured by way of carburizing hardening, precision grinding. Its precision is up to Grade 6(GB10095-88). Hardness of tooth flank is HRC54-62. Thrust bearing is in front of output hollow shaft to accommodate screw-rod back pressure forces. Bearings, oil seals and some other standard units are quality products and they can also be imported goods to meet customers' requirements. This kind of speed reducer has the characteristic of small volume, high load capacity, stable transmission, low noise, high efficiency. They properties reach levels of foreign products of the same kind and it can take place of them.

Extruder gearbox Brief Introduction

1. ZLYJ series plastic extruding gear reducer is a transmission part that possesses high precision hard gear surface and thrust block designed for plastic screw extruder.

2.The design of product adapts all kinds of norm specified in ZBJ19009-88/it features that gear and axis parts are made of high strength alloy steel.

3.The gear is processes by carburization, quenching and tooth grinding process.

4.The precision of gear is grade 6 specified in GB1009588.

5.The hardness of gear surface is HRC54~62. At front end of hollow input axis there is large specification thrust bearing that will bear axial thrust force while the screw is working.

6.The complete machine features compact, high in bearing capacity, stable in transmission, low noise, high efficiency, etc.

Extruder gearbox Application Environment:

1. The input rotation of prime mover shall be ≤1500rpm

2. The peripheral speed of gear drive shall be ≤20m/s

3. The working ambient temperature shall be within -40~45°C.Preheat the lubrication oil to above 0°C when the ambient temperature is below 0°C. Rotation is available both forwards and backwards. However, the high speed shaft of some types of reducers has a single way oil pump directing as defaulted to the output shaft which rotates clockwise.

Extruder gearbox Applications:

Plastic Extruders

Rubber Extruders

Single Screw Extruders (ZLYJ/ZSYJ Series Extruder Gearbox)

Conical Twin Screw Extruders (SZ Series Extruder Gearbox)

Plastic extruding gear reducer Installation:Horizontal Mounted Vertical Mounted

Extruder gearbox Lubrication: Oil Dip and Splash Lubrication Forced Lubrication (Additional Oil Pump)

Plastic extruding gear reducer Cooling: Natural Cooling Auxiliary Cooling Devices