China gearbox speed reducer manufacturer

Electric motor gearbox supplier, industrial motor reducer manufacturer

China gearbox speed reducer manufacturer

Electric motor gearbox supplier, industrial motor reducer manufacturer

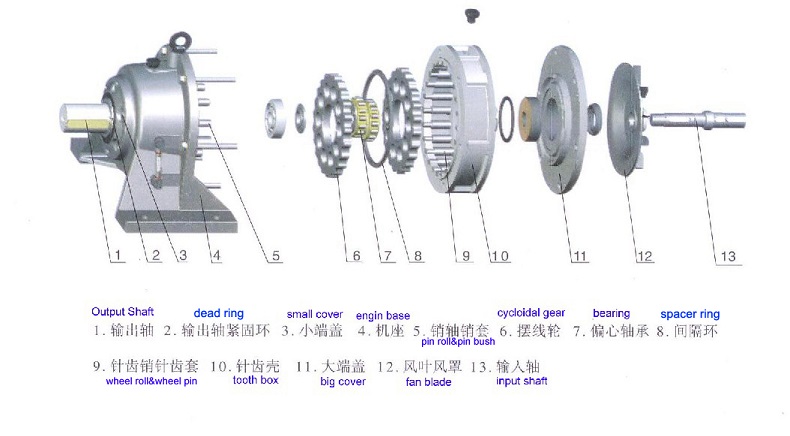

BLED10 cycloid planetary gear

Description

cycloid inline drives characteristics

1. Double Reduction Ratios has solid shaft output, hollow shaft output and contract disk hollow shaft output,which can be installed horizontally , vertically. cycloid inline drives is made of high strength quality alloy steel through quenching and possesses high efficiency and long life gear .Othermore, Double Reduction Ratios can bear large axial and radial load.Features is low in run noise, high in reliability, compact and so on.

2.The housing of one size cycloid inline drives can realize parallel shaft,right-angle shaft modes and horizontal,vertical mounting modes.Variety of components is reducible, the number of reducer's mode is augmentable.

3.Sound-absorbable structure, lager surface, big fan reduce temperature and noise, advanced grinding process of cylindrical gear and bevel gear improve stability and transmit power more efficeintly for Double Reduction Ratios.

4. cycloid inline drivesinput mode : motor connected flange ,shaft input.

Double Reduction Ratios output mode: solid shaft with flat key, hollow shaft with flat key, hollow shaft with shrink hollow or solid shaft with involute splines , solid shaft with flange.

5. cycloid inline drivesmounting mode: Foot-mounted, flange-mounted, swing base-mounted, torque-arm-mounted.

Double Reduction Ratios detailed parameter:

1. cycloid inline drivesoutput speed(Rpm): 11-167

2. Double Reduction Ratios output torque(Nm):80-22000

3. cycloid inline drivespower(Kw): 0.18-55

4. Double Reduction Ratios range of Ratio for Single Stage: 9,11,17,23,29,35,43,59,71,87

cycloid inline drives range of Ratio for Multi-Speed Drive:

121,187,289,391,473,595,731,841,1003,1225,1505,1849,2065,2537,3481,4189,5133,7569

Safety Packing Method of Double Reduction Ratios

1.Inside :Plastic bags with Chemical Desiccant For Gear Housing

2.Middle :Individual Carton packaging

3.Outside :Wooden Box

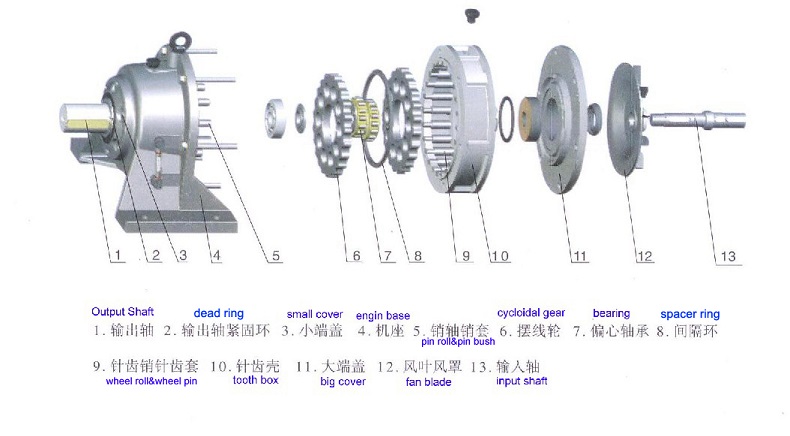

cycloid inline drives characteristics

1. Double Reduction Ratios has solid shaft output, hollow shaft output and contract disk hollow shaft output,which can be installed horizontally , vertically. cycloid inline drives is made of high strength quality alloy steel through quenching and possesses high efficiency and long life gear .Othermore, Double Reduction Ratios can bear large axial and radial load.Features is low in run noise, high in reliability, compact and so on.

2.The housing of one size cycloid inline drives can realize parallel shaft,right-angle shaft modes and horizontal,vertical mounting modes.Variety of components is reducible, the number of reducer's mode is augmentable.

3.Sound-absorbable structure, lager surface, big fan reduce temperature and noise, advanced grinding process of cylindrical gear and bevel gear improve stability and transmit power more efficeintly for Double Reduction Ratios.

4. cycloid inline drivesinput mode : motor connected flange ,shaft input.

Double Reduction Ratios output mode: solid shaft with flat key, hollow shaft with flat key, hollow shaft with shrink hollow or solid shaft with involute splines , solid shaft with flange.

5. cycloid inline drivesmounting mode: Foot-mounted, flange-mounted, swing base-mounted, torque-arm-mounted.

Double Reduction Ratios detailed parameter:

1. cycloid inline drivesoutput speed(Rpm): 11-167

2. Double Reduction Ratios output torque(Nm):80-22000

3. cycloid inline drivespower(Kw): 0.18-55

4. Double Reduction Ratios range of Ratio for Single Stage: 9,11,17,23,29,35,43,59,71,87

cycloid inline drives range of Ratio for Multi-Speed Drive:

121,187,289,391,473,595,731,841,1003,1225,1505,1849,2065,2537,3481,4189,5133,7569

Safety Packing Method of Double Reduction Ratios

1.Inside :Plastic bags with Chemical Desiccant For Gear Housing

2.Middle :Individual Carton packaging

3.Outside :Wooden Box

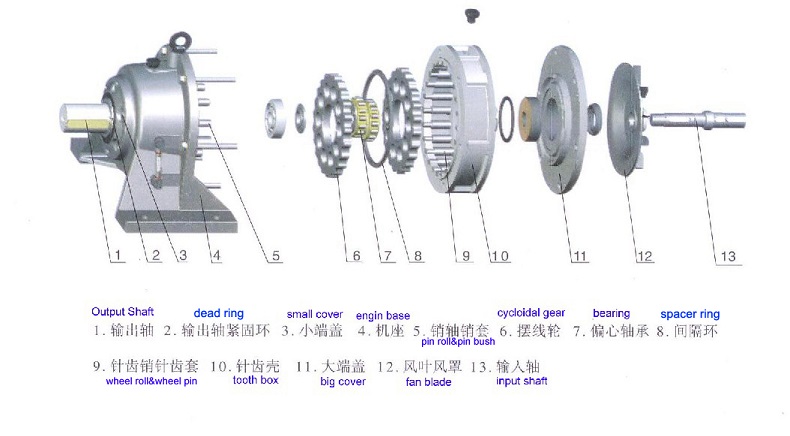

cycloid inline drives characteristics

1. Double Reduction Ratios has solid shaft output, hollow shaft output and contract disk hollow shaft output,which can be installed horizontally , vertically. cycloid inline drives is made of high strength quality alloy steel through quenching and possesses high efficiency and long life gear .Othermore, Double Reduction Ratios can bear large axial and radial load.Features is low in run noise, high in reliability, compact and so on.

2.The housing of one size cycloid inline drives can realize parallel shaft,right-angle shaft modes and horizontal,vertical mounting modes.Variety of components is reducible, the number of reducer's mode is augmentable.

3.Sound-absorbable structure, lager surface, big fan reduce temperature and noise, advanced grinding process of cylindrical gear and bevel gear improve stability and transmit power more efficeintly for Double Reduction Ratios.

4. cycloid inline drivesinput mode : motor connected flange ,shaft input.

Double Reduction Ratios output mode: solid shaft with flat key, hollow shaft with flat key, hollow shaft with shrink hollow or solid shaft with involute splines , solid shaft with flange.

5. cycloid inline drivesmounting mode: Foot-mounted, flange-mounted, swing base-mounted, torque-arm-mounted.

Double Reduction Ratios detailed parameter:

1. cycloid inline drivesoutput speed(Rpm): 11-167

2. Double Reduction Ratios output torque(Nm):80-22000

3. cycloid inline drivespower(Kw): 0.18-55

4. Double Reduction Ratios range of Ratio for Single Stage: 9,11,17,23,29,35,43,59,71,87

cycloid inline drives range of Ratio for Multi-Speed Drive:

121,187,289,391,473,595,731,841,1003,1225,1505,1849,2065,2537,3481,4189,5133,7569

Safety Packing Method of Double Reduction Ratios

1.Inside :Plastic bags with Chemical Desiccant For Gear Housing

2.Middle :Individual Carton packaging

3.Outside :Wooden Box

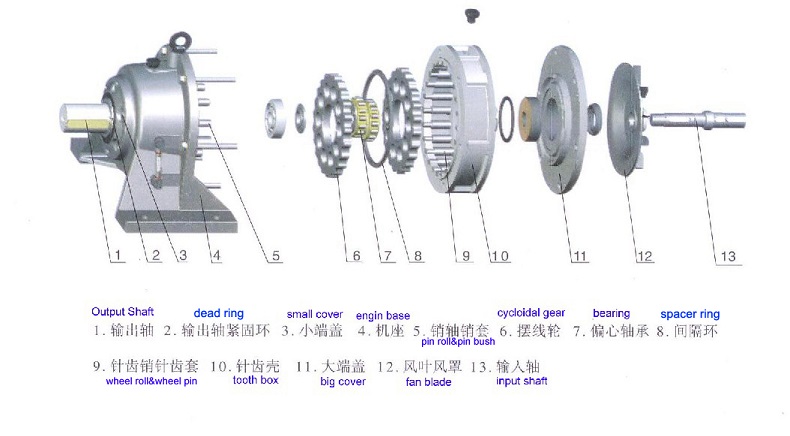

cycloid inline drives characteristics

1. Double Reduction Ratios has solid shaft output, hollow shaft output and contract disk hollow shaft output,which can be installed horizontally , vertically. cycloid inline drives is made of high strength quality alloy steel through quenching and possesses high efficiency and long life gear .Othermore, Double Reduction Ratios can bear large axial and radial load.Features is low in run noise, high in reliability, compact and so on.

2.The housing of one size cycloid inline drives can realize parallel shaft,right-angle shaft modes and horizontal,vertical mounting modes.Variety of components is reducible, the number of reducer's mode is augmentable.

3.Sound-absorbable structure, lager surface, big fan reduce temperature and noise, advanced grinding process of cylindrical gear and bevel gear improve stability and transmit power more efficeintly for Double Reduction Ratios.

4. cycloid inline drivesinput mode : motor connected flange ,shaft input.

Double Reduction Ratios output mode: solid shaft with flat key, hollow shaft with flat key, hollow shaft with shrink hollow or solid shaft with involute splines , solid shaft with flange.

5. cycloid inline drivesmounting mode: Foot-mounted, flange-mounted, swing base-mounted, torque-arm-mounted.

Double Reduction Ratios detailed parameter:

1. cycloid inline drivesoutput speed(Rpm): 11-167

2. Double Reduction Ratios output torque(Nm):80-22000

3. cycloid inline drivespower(Kw): 0.18-55

4. Double Reduction Ratios range of Ratio for Single Stage: 9,11,17,23,29,35,43,59,71,87

cycloid inline drives range of Ratio for Multi-Speed Drive:

121,187,289,391,473,595,731,841,1003,1225,1505,1849,2065,2537,3481,4189,5133,7569

Safety Packing Method of Double Reduction Ratios

1.Inside :Plastic bags with Chemical Desiccant For Gear Housing

2.Middle :Individual Carton packaging

3.Outside :Wooden Box

v