The industrial mixers are in many mounting ways and various types. But with a same function, make the materials mixed into powder, mud, liquid and other shapes. For the industrial mixer equipment, the gear reducers are the most import part which is supplying power for the entire system. It is the source of the power, the torque and so it's so important.

Our gear reducers are widely used in industrial mixer's equipment and each type gives a stable and quiet torque supplying.

The followings are the main products:

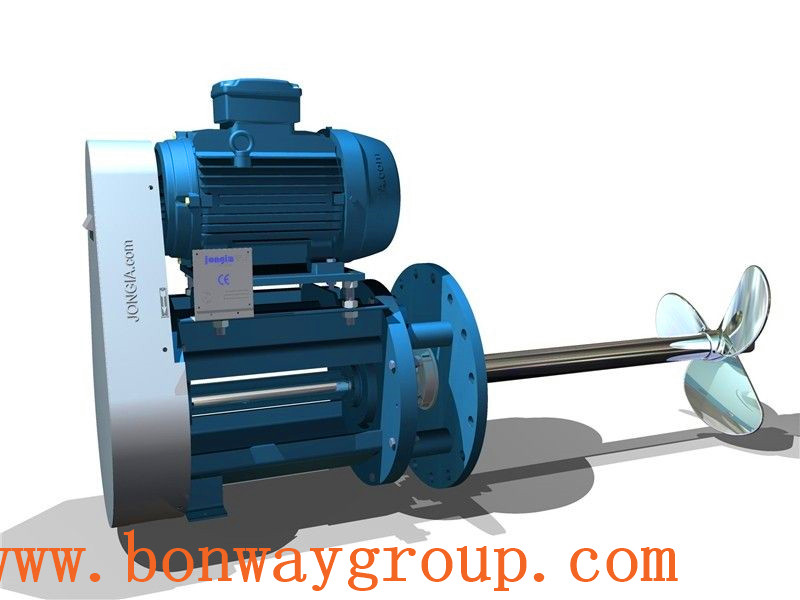

1. Electric motor with pulley belt type

This is a electric motor type with pulley belt to reduce the speed of the electric motor and make torques. 2 SERIES CAST IRON THREE PHASE/TRIPHASE ELECTRIC MOTOR Adopting the national uniform design,Y2 series three phase induction motors,are conformity with IEC34 1 and JB/T8680.1 1998 standards,also up to the international advanced level 90' s as substitute of Y series induction motors,It possesses sophisticated features such as new structure, good appearance,slight vibration ,low noise etc.

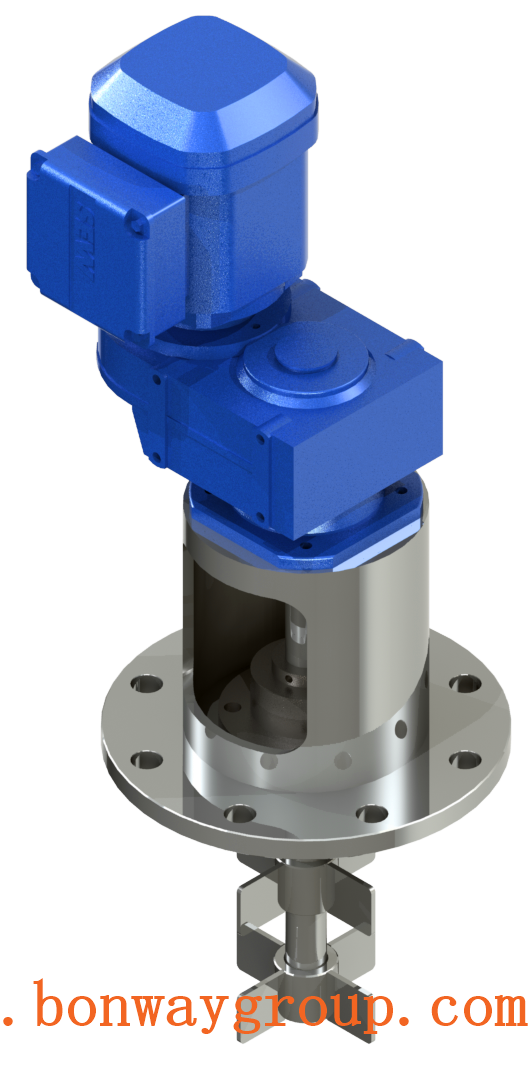

2. Cycloidal vertical shaft with rack.

Type: Cycloidal-Pin Gear Speed Reducer Input Speed: 1400-1500rmp Output Speed: 14-280rpm

Certification: ISO9001 CE 3C Ex Power:0.18-132KW Warranty: 1Years

3. Parallel shaft helical gear motor type

Parallel shaft helical geared motor is characterized by compact structure, light weight, large torque and excellent performance. As a new reducing transmission system, it is advantaged in design and manufacture on the basis of the modularized combination, which can meet client’s requirement on connection and installation. Prompt delivery within short time. It is made of rib-reinforced rigid case and premium alloy-steel gear which is hardened by carbon penetration and grinded precisely. Stable in running, low noise, large in load, low in consumption, efficient in transmission, low in temperature rise, and long in service life. The mounting style are footing, flange, torque arm and so on. The output style are shaft, hollow shaft, the alpine and shrink disc are for choice.

4.Helical worm geared motors with right angle mounting.

It adopts the combination of helical gear and worm, and vertical output so that structure is compact and the speed ratio is large.

Installation type: foot, flange, small flange, torque arm

Output type: hollow shaft, solid shaft, hollow shaft with shrink disk, spline hollow shaft

Input type: motor, input shaft, flange

Reducing ratio: 23.8-67.8, the combination 26688.

Average efficiency: 77% for speed ratio of 23.8-67.8, 62% for speed ratio of 73.7-389, 57% for EWS/EWR.

Rotational direction of worm: left handed